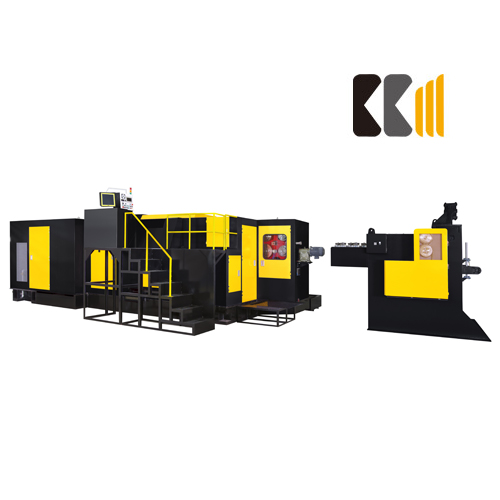

STANDARD & LONG STROKE BOLT FORMER

STANDARD & LONG STROKE BOLT FORMER

FEATURE

4 and 5 stations bolt former is for standard fastener production with certain quality and production speed.

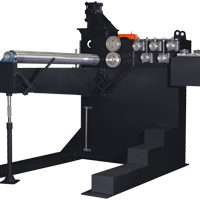

Horizontal Wire Stand

Suitable for bigger machine, easy to change wire and straighten.

Material Return Motor

Assistant wire in and out, make operation more conveniently.

K.O. adjustment by handwheel

Using handwheel and number display function to adjust the length of K.O. easily.

Rear Shaft

Decreasing the volume of flywheel, increasing the torque.

Wire Feeding Length Adjustment by Digital Controller

The digital motor equipes the one way bearing which is able to adjust the length of the wire by digital controller; Saving operation time and labor cost.

Horizontal Cylinder Plunger Type K.O. System

Design for extra long length bolt, will make K.O. main rod force taken directly to avoid the broken issue.

Noise Proof Cover

Decreasing the noise issue to imporve the production enivronment.

Stopper Length Adjustment by Handwheel

Using handwheel and display function to help operators to adjust the cutting length.

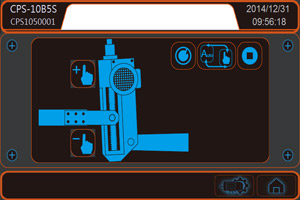

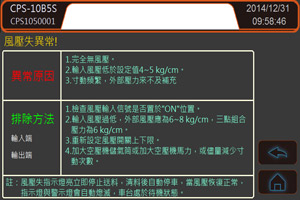

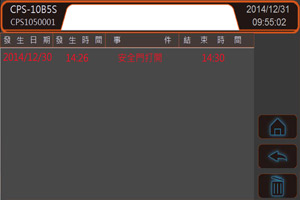

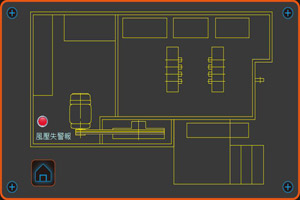

The human machine interface was developed by CCM 's R&D team, it could be flexible adjustment depend on customer's request.

Human Machine Interface

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Operation Panel

Abnormity Removing

Error Log

Abnormity Indication

CPS SERIES 4 STATION BOLT FORMER

| MODEL | CBS 10B |

CBS 13B |

CBS 17B |

CBS 19B |

CBS 24B |

CBS 30B |

CBS 36B |

||

|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | |||||||||

| FORGING STATION | 4 | ||||||||

| PRODUCTS | SIZE | 1/4 (M6) |

5/16 (M8) |

3/8 (M10) |

1/2 (M12) |

5/8 (M16) |

3/4 (M20) |

1 (M24) |

|

| MAX.L(mm) | 65 | 72 | 100 | 125 | 150 | 200 | 250 | ||

| MIN.L. (mm) | 14 | 16 | 16 | 20 | 25 | 40 | 60 | ||

| CUT-OFF DIA MAX(mm) | 8 | 10 | 12 | 15 | 18 | 23 | 29 | ||

| CUT-OFF LENGTH MAX(mm) | 100 | 110 | 140 | 165 | 200 | 270 | 320 | ||

| KICK-OUT LENGTH MAX(mm) | 80 | 90 | 120 | 145 | 175 | 240 | 290 | ||

| P.K.O LENGTH MAX (mm) | 16 | 20 | 35 | 42 | 45 | 35 | 60 | ||

| CUT-OFF QUILL (D X L) (mm) | 28×46 | 35×56 | 40×66 | 60×120 | 60×100 | 75×120 | 90×140 | ||

| MAIN DIE HOLE (D X L) (mm) | 50×85 | 60×105 | 80×135 | 95×165 | 100×195 | 125×240 | 160×294 | ||

| DIES PITCH (mm) | 69 | 87 | 93 | 114 | 126 | 138 | 175 | ||

| PUNCH HOLE (D X L) (mm) | 40×77 | 45×110 | 50×111 | 60×120 | 75×165 | 90×197 | 105×232 | ||

| RAM STROKE (mm) | 140 | 150 | 160 | 240 | 280 | 360 | 440 | ||

| FORGING POWER (ton) | 40 | 65 | 85 | 120 | 175 | 220 | 320 | ||

| MAX. OUTPUT (pcs/minute) | 210 | 180 | 150 | 150 | 100 | 80 | 60 | ||

| MAIN MOTOR (hp) | 15 | 20 | 30 | 50 | 75 | 100 | 125 | ||

| APPROX.WT.(ton) | 9 | 11 | 17.5 | 27 | 49 | 64 | 100 | ||